What Are the Essential Steps for Installing a DC Motor?Installing a DC motor correctly is crucial for ensuring optimal performance and longevity. Mercury Motion, a leading gear motor manufacturer, provides a detailed guide to help you through the installation process, ensuring that your motor is set up correctly from the start. This guide covers everything from preparing the installation site to securing the motor in place. How Do You Prepare for the Installation?Before installing your DC motor, it's important to prepare both the motor and the installation site. Start by reading the manufacturer’s manual to understand the specific requirements and recommendations for your motor model. Mercury Motion’s DC motors come with detailed documentation to guide you through this process. 1.Check the Site: Ensure that the installation site is clean, dry, and free from dust and debris. The site should also have adequate ventilation to prevent the motor from overheating during operation. 2.Inspect the Motor: Before installation, inspect the motor for any visible damage that might have occurred during shipping. Check the terminals, housing, and shaft for any signs of wear or damage. 3.Gather Tools and Materials: You will need tools such as wrenches, screwdrivers, and a multimeter. Ensure that you have all necessary mounting hardware and electrical connectors ready.

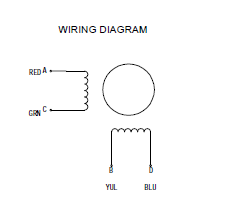

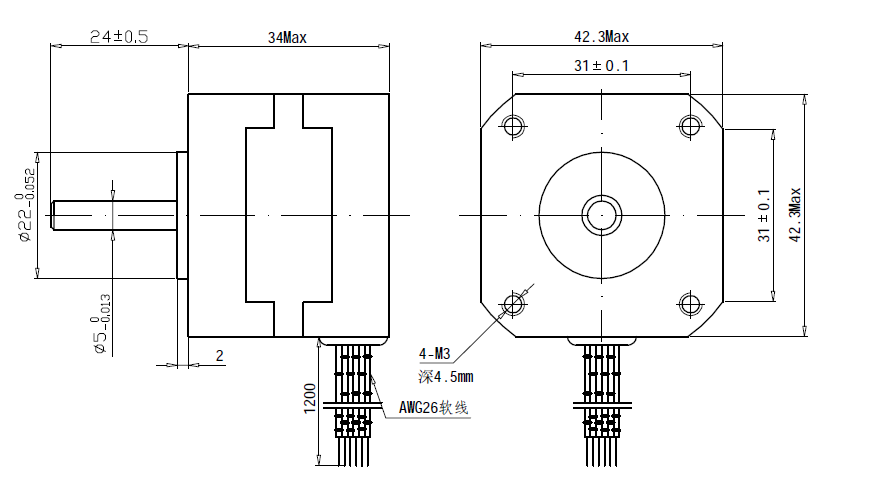

What Is the Correct Way to Mount the DC Motor?Proper mounting is critical for the motor's stability and operation. Mercury Motion recommends the following steps to securely mount your DC motor: 1.Position the Motor: Place the motor on the mounting surface, ensuring that the shaft is aligned with the driven load (e.g., a pulley, gear, or conveyor belt). 2.Secure the Motor: Use the appropriate bolts and washers to secure the motor to the mounting base. Tighten the bolts evenly to avoid misalignment or stress on the motor frame. 3.Check Alignment: After securing the motor, check the alignment of the motor shaft with the driven load. Misalignment can lead to excessive wear, noise, and vibration, potentially reducing the motor's lifespan. How Do You Wire the DC Motor Correctly?Wiring your DC motor correctly is essential for safe and efficient operation. Mercury Motion's DC motors are designed for easy wiring, but following the correct procedures is still crucial: 1.Refer to the Wiring Diagram: Consult the wiring diagram provided in the motor’s manual. This diagram will show you the correct connections for the power supply, ground, and control terminals. 2.Connect Power Supply: Connect the positive and negative terminals of the power supply to the corresponding terminals on the motor. Ensure that the voltage and current ratings of the power supply match the motor’s specifications. 3.Ground the Motor: Proper grounding is essential for safety. Connect the motor's ground terminal to a suitable grounding point to prevent electrical shock and reduce the risk of electrical noise affecting the motor's operation. 4.Test the Connections: After wiring, use a multimeter to check for continuity and ensure that there are no short circuits. Verify that the connections are secure and that the motor is ready for operation. How Do You Configure the DC Motor for Optimal Performance?Configuring your DC motor involves adjusting settings such as speed, torque, and direction to match your application’s requirements. Mercury Motion’s DC motors offer flexibility in configuration, allowing you to tailor the motor’s performance to your specific needs: 1.Adjust the Speed: Use the motor controller to set the desired speed. Depending on your application, you may need to fine-tune the speed settings to achieve the right balance between performance and efficiency. 2.Set the Torque Limit: Configure the motor’s torque limit based on the load requirements. Setting the correct torque prevents the motor from overloading and ensures that it operates within safe parameters. 3.Configure the Direction: If your application requires the motor to run in a specific direction, adjust the wiring or controller settings accordingly. Some controllers allow for easy reversal of the motor direction via a switch or software settings. What Are the Final Steps Before Operating the DC Motor?Before operating your DC motor, it’s important to perform a few final checks to ensure everything is in order: 1.Double-Check Connections: Verify that all electrical connections are secure and that there are no loose wires or exposed terminals. 2.Inspect Mounting: Ensure that the motor is firmly mounted and that there is no misalignment between the motor shaft and the driven load. 3.Test Run the Motor: Perform a test run without a load to check for smooth operation. Listen for any unusual noises and monitor the motor for excessive vibration or heat. Why Trust Mercury Motion for Your DC Motor Needs?Mercury Motion is dedicated to providing high-quality DC motors that are reliable, efficient, and easy to install. Our motors are designed with user-friendly features that make installation and configuration straightforward, even for those with limited experience. With detailed manuals, expert customer support, and a commitment to innovation, Mercury Motion is the trusted choice for all your gear motor needs. In conclusion, installing and configuring a DC motor correctly is essential for ensuring optimal performance and longevity. By following the steps outlined in this guide, you can install and set up your Mercury Motion DC motor with confidence, knowing that it will provide reliable service for years to come. Whether you’re working on a new project or upgrading an existing system, Mercury Motion’s DC motors are the ideal choice for a wide range of applications.

|